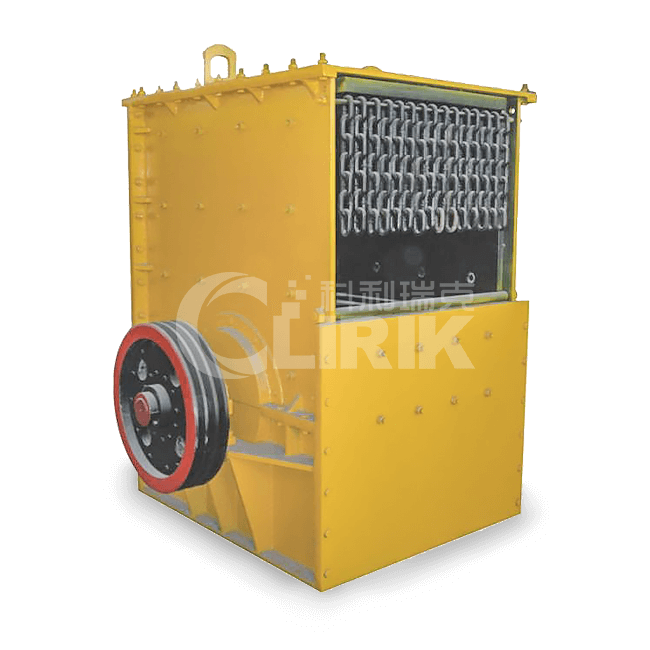

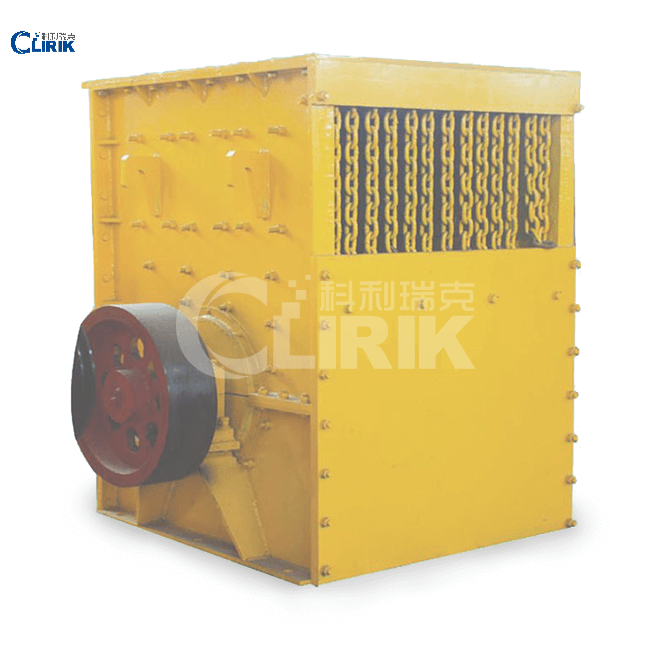

Cabinet Hammer Crusher

Table of Contents

Cabinet Hammer Crusher

Capacity: 30-160t/h

Max feeding size: 800mm

Processing ability: 30-160t/h

Range of application: Almost all minerals, such as quartz, feldspar, mica, calcite, gypsum, fluorite, limestone, soil, clay, marble, granite, pebble, coal, slag, iron ore, copper ore, manganeseore, refractory material, glass, etc.

Product Parameter Of Cabinet Hammer Crusher

| Model | PC600 | PC800 | PC1000 | PC1200 |

| Rotor speed(r.p.mm) | 600-800 | 650-750 | 650-750 | 600-750 |

| Max feeding size(mm) | 550 | 780 | 780 | 800 |

| Finished particle size(mm) | ≦50 | ≦50 | ≦50 | ≦50 |

| capacity (t/h) | 30-50 | 40-80 | 50-100 | 100-160 |

| Powder(KW) | 40-55 | 75-90 | 90-110 | 110-132 |

| Weight( kg) | 4200 | 4800 | 6500 | 8300 |

Note: This specification is just referencing, any changes are subject to the products.

Product Overview Of Cabinet Hammer Crusher

Cabinet Hammer Crusher, referred to as box breaking or heavy hammer breaking, is a kind of high power, large crushing ratio, high productivity crusher, very suitable for processing 450-1400mm to 100mm below small size of large raw materials, widely used in mining, cement, building materials, chemical industry and other industries.

Cabinet Hammer Crusher Application

Cabinet Hammer Crusher, Suitable for crushing raw materials with compressive strength less than 200Mpa, such as quartz, feldspar, mica, calcite, gypsum, fluorite, limestone, soil, clay, marble, granite, pebble, coal, slag, iron ore, copper ore, manganese ore, refractory materials, glass and so on.

Working Principle Of Cabinet Hammer Crusher

In cabinet hammer crusher gravity, hammers do high-speed circular motion along with rotors driven by motor.

After being fed into crusher, large stones are stacking on the shelf which is particular to box crusher. Raw materials are smashed into smaller pieces by hammers. Right following the fist crushing, unqualified pieces hit against the impact plate with new fed material at a tangent to circular motion of Hammers. So once for all, material undergo two steps of crushing, from coarse to medium size then to qualified small size. Finished product are sieved through screen and discharged at a uniform particle size.

Product Advantage of Cabinet Hammer Crusher

- High yield and stable performance.

- Large feed size, crushing ratio, uniform discharge.

- The rate of finished products is high, and the passing rate of finished products particles accounts for about 85%.

- Cabinet hammer crusher hammer shaft installation is adjustable, hammer head long life.

- Grid size is adjustable, product particle size is controllable, particle shape is good.

- Cabinet hammer crusher case can be turned over, more convenient maintenance.

- Square shank bolts, impact and wear resistance.

- Supporting small power, low energy consumption, easy maintenance, less wearing parts.

- Coarse and medium crushing in one step, simplify the process.

- High wear-resistant material hammer head, grate plate and counter plate, longer service life.

Introduction Manufacturer Of Cabinet Hammer Crusher

Our Company

SHANGHAI CLIRIK MACHINERY CO., LTD located in PUDONG New district of Shanghai china as a professional enterprise, which is specializing in research, manufacture and sales of all kinds of mining equipment. Our company has already formed a full set of modern production line, equipped with intelligent, standardized testing and controlling laboratories, owned a professional team for R&D, production, sales and service.

Our Certification

Our company has obtained a number of product patent certificates. The company attaches great importance to independent intellectual property development, independent intellectual property protection, and continuously expands the investment in product new technology research and development, and actively stimulates the innovation consciousness of research and development personnel.

Our Exhibition

We participate in the BMW exhibition, in the exhibition our products are loved by customers at home and abroad.

Our Service

1.one year guarantee for whole machine except for wear parts.

2.24 hours technical support by email.

3.calling service.

4.user manual available.

5.reminding for the service life of the wearing parts.

6.installation guide for clients from both China and abroad.

7.maintance and replacement service.

8.whole process trainling and guidance from our technicians.

Other Product Recommendations

HGM Series Micro Powder Grinding Mill↗

HGM Series Micro Powder Grinding Mill is stable quality,easy operation and maintenance.

CLUM Series Ultrafine Vertical Powder Grinding Mill↗

CLUM series Ultrafine Vertical Powder Grinding Mill is a new type of grinding equipment produced which integrates grinding, grading and conveying.

YGM Series High Pressure Suspension Grinding Mill ↗

YGM series high pressure suspension grinding machine low investment cost, easy operation and maintenance.

- Previous: Ball Mill

- Next: CLG Series Powder Surface Coating Machine