CLRM Series Gypsum Powder Enhanced Roller Grinding Mill

Table of Contents

- 1 Product overview of CLRM series gypsum powder enhanced roller grinding mill

- 2 Product parameter of CLRM series gypsum powder enhanced roller grinding mill

- 3 Working principle of CLRM series gypsum powder enhanced roller grinding mill

- 4 Product features of CLRM series gypsum powder enhanced roller grinding mill

- 5 Introduction manufacturers of CLRM series gypsum powder enhanced roller grinding mill

- 6 FAQ

Product overview of CLRM series gypsum powder enhanced roller grinding mill

CLRM series gypsum powder enhanced roller grinding mill, also known as enhanced Raymond grinding mill, can grind non-flammable and explosive materials with Mohs hardness not greater than 6 and humidity below 6%. Its main components include main engine, reducer, analyzer, pipeline device, blower, dust collector, jaw crusher, bucket elevator, electromagnetic vibrating feeder, electric control system, etc.

CLRM Series Gypsum Powder Enhanced Roller Grinding Mill

Model: CLUR series

Brand: Clirik

Processing ability: 1-35 t/h

Fineness: 80-500 mesh

Max feeding size: 35 mm

Range of application: Calcium carbonate, limestone, gypsum, graphite, bentonite, talc, rock phosphate, coal, bauxite…

CLRM series gypsum powder enhanced roller grinding mill is widely used in the fields of metallurgy, construction, chemical industry, mining, highway construction etc. The granularity of the finished powder size can be adjusted between 80 – 500 meshes (180- 30 micron). Examples of processing materials include quartz, feldspar, barite, calcite carbonate, limestone, talc, ceramic, iron ore, carborundum, bauxite, rock phosphate, coal and other materials, a total of about 400 kinds of materials.

Product parameter of CLRM series gypsum powder enhanced roller grinding mill

| Model | Roller | Ring | Main Shaft Speed (r/min) |

Feeding Size (mm) |

Finished Size (mesh) |

Motor (kw) |

Capacity (t/h) |

||

| Quantity (piece) |

Size (mm) |

External Dia (mm) |

Height (mm) |

||||||

| CLRM9720 | 3-4 | 320*200 | 1077 | 200 | 145 | <20 | 80-500 | 45*15*37 | 1-7 |

| CLRM1280 | 3 | 370*2*40 | 1280 | 240 | 125 | <20 | 80-400 | 75*15*55 | 2-12 |

| CLRM1300 | 4 | 410*2*80 | 1390 | 280 | 112 | <20 | 80-400 | 110*22*90 | 3-15 |

| CLRM1620 | 4 | 450*300 | 1620 | 300 | 102 | ><20 | 80-400 | 160*30*132 | 5-20 |

| CLRM1700 A | 4 | 510*300 | 1700 | 300 | 102 | <30 | 80-325 | 185*37*160 | 6-25 |

| CLRM1720 | 4 | 510*300 | 1850 | 300 | 92 | <35 | 80-325 | 250*45*185 | 6-25 |

| CLRM1900 A | 4 | 600*300 | 1900 | 300 | 92 | <35 | 80-325 | 250*45*220 | 8-32 |

| CLRM2150 | 4 | 600*300 | 2150 | 300 | 85 | <35 | 80-325 | 315*45*280 | 12-35 |

Note: for the motor data in the above sheet such as “45*15*37” means the main motor “classifier motor” blower motor.

Working principle of CLRM series gypsum powder enhanced roller grinding mill

Big materials are crushed by jaw crusher to the required particle sizes, and carried by bucket elevator to the storage hopper, and are fed evenly and continuously by vibrating feeder into the main unit for grinding. The grinded powder is carried by the airflow from the blower to the cassifier to be classified, the particles which meet the fineness enter cyclone collector through pipe, are separated and collected there. They are discharged at the discharging valve to become finished products; the airflow is sucked to the blower by a return pipe on the top of a cyclone collector. The whole airflow system is a sealed circulation, and is circulated under positive and negative air pressure.

Product features of CLRM series gypsum powder enhanced roller grinding mill

1. Optimized grinding part, increase grinding efficiency.

Compared with the previous mill, the grind pressure increased 10%, grinding area up 15 -20%. Optimized the roller layout, escalated the efficient grinding space.

2. Triple vibrating damping for working stability.

Triple damping to resist the vibrating transmit in the main unit base, volute aiflow house, unit body, grinding part. Be sure of the stable grinding condition.

3. New type impeller of cassifier with VFD.

Equipped the new cage type impeller for lassifier, adjust the speed freely by VFD, enlarge the output size range to 80 – 500mesh.

4. Grinding device adopts superimposed multistage seal, prolong the lubricating cycle.

Make CLRM series gypsum powder enhanced roller grinding mill the maintenance convenient, cost saving.

Introduction manufacturers of CLRM series gypsum powder enhanced roller grinding mill

Company profile

Shanghai Clirik Machine Co., Ltd. has a professional technical force and perfect production capacity. The company’s products are widely used in mining, road construction, bridge construction, housing construction and other industries, crusher, ultra-fine grinding mill, feeder, vibrating screen, sand washing machine, conveyor and other equipment and series of products, all passed the ISO9001:2000 standard quality certification.

Our Technology

Clirik has more than 12,000 square meters of standardized production plant, including a processing workshop, assembly workshop, painting and sandblasting workshop, trial machine debugging workshop, finished product placement workshop, etc. The workshop is equipped with more than 100 high-end CNC machine tools of well-known foreign brands.

From drawing, assembly to debugging, the equipment manufacturing has gone through thousands of processes, including resizing, cutting, grinding, trimming, heating, forging, turning, milling, grinding and drilling, inspection, painting, assembly and test machine. Each manufacturing process is repeatedly verified by our engineers to ensure the reliability and integrity of each device. Raw materials are related to the quality of products. Our engineers have strict requirements on the selection of raw materials. National standard steel is used.

Our Transportation

We can not only provide you with express delivery, sea transportation, land transportation, air transportation, self-transport and other ways to deliver goods according to your needs, but also package the main machine and parts of the grinding equipment you buy to avoid damage in the process of transportation, to ensure that you can assemble and produce the equipment after receiving it.

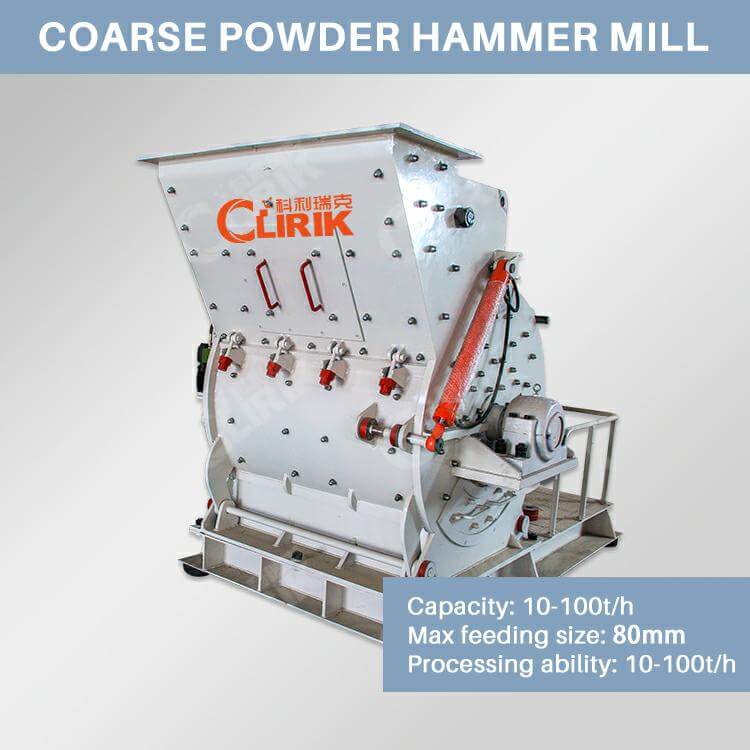

Hot Product

In addition to CLRM series gypsum powder enhanced roller grinding mill, the company also has other related gypsum powder production line equipment.

FAQ

Because there are different kinds of CLRM series gypsum powder enhanced roller grinding mill, so our CLRM series enhanced Raymond mill has different prices, I need to ask you some details to send you the more suitable quotation:

1. Which kind of material are you going to grind?

(Dolomite; calcite; quartz; basalt; barite; feldspar; gravel; bentonite; gypsum; granite; coal; slag; pebble; others)

2. What’s the production capacity you want? How many tons or cubic meters per hour?

( > 100 TPH > 50 TPH > 30 TPH > 10 TH > 1 TPH < 1 TPH)

3. What’s the granularity of the final products you need?

(in milimeter, micron or mesh)

4. What’s the max input size of the material?

(In inch, centimeter or millimeter)

We will give you factory price with full specification, so please leave us an inquiry to know more details about price, packaging, shipping and discount.