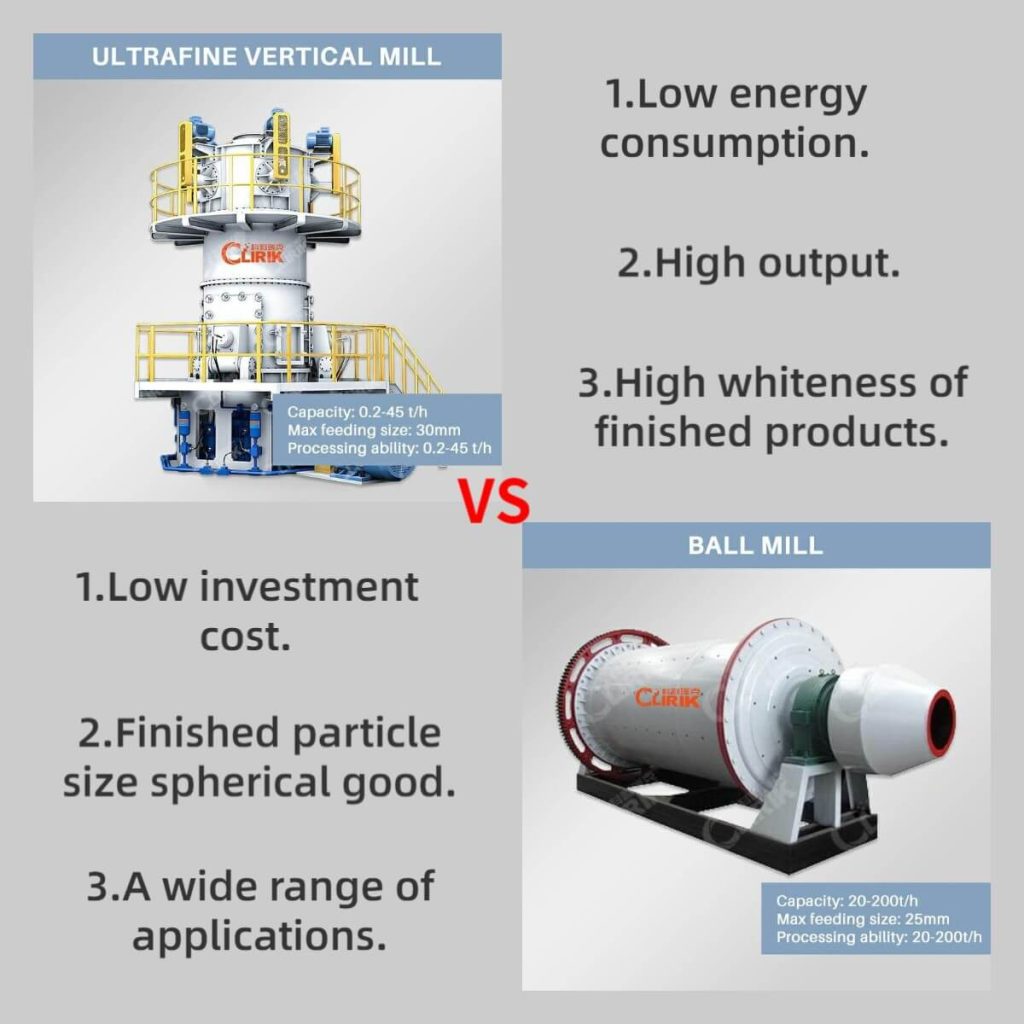

Comparison of gypsum powder ultrafine vertical mill and ball mill

Release Time:2022-10-13

Gypsum powder ultrafine vertical mill and ball mill are common equipment for grinding ultrafine gypsum powder. What’s the difference between them? Let’s learn about it today!

Gypsum powder ultrafine vertical mill

Energy consumption: Gypsum powder ultrafine vertical mill has low power consumption. Compared with ball mill, it can reduce the power cost by 30%~50% when the particle size of raw material grinding products is the same.

Product flexibility: High efficiency and flexible regulation of product categories, can be a one-time production of 9,500 specific surface area (d97=20) μm)~25,000 (d97= 10 μm)cm2/g Super fine powder.

Drying capacity: Gypsum powder ultrafine vertical mill has higher drying ability. The new roller mill can introduce larger air flow rate, and can feed and dry with higher water content.

Device configuration space: The Gypsum powder ultrafine vertical mill station area is small, occupying only 50-70% of the space of the ball mill.

Feed particle size: Compared with the gypsum powder ball mill, the ultrafine vertical roller mill has a larger grinding particle size, which can directly grind raw materials with a larger particle size without excessive crushing.

Fineness of product: CLUM series gypsum powder ultra-fine grinding machine uses high and adjustable grinding pressure, can produce a large amount of fine powder, the final grinding product fineness is better.

Grinding product replacement time: Different materials can be ground on the same ultrafine powder vertical roller mill in a very short time.

Contamination of abrasive materials: Gypsum powder ultrafine vertical grinding machine is no abrasive medium wear, The degree of contamination of the abrasive material is less, and the final product is more white.

Grinding efficiency: The CLUM series superfine vertical mill grinds materials by high-pressure wheel, with high grinding efficiency and small wear degree.

Initial investment cost: Compared with ball mill, gypsum powder ultrafine vertical mill has high investment cost.

Operating cost: Gypsum powder ultrafine vertical mill has no grinding medium consumption and low power consumption, low operating cost.

Noise: The workshop noise of gypsum powder ultrafine mill is much lower than that of ball mill.

Product particle shape: The finished product sphericity of gypsum powder ultrafine vertical grinding material is slightly worse.

Sensitivity to external conditions: Gypsum powder ultrafine vertical mill is sensitive to metal foreign bodies.

Gypsum powder ball mill

Energy consumption: Gypsum powder ball mill has high power consumption.

Product flexibility: Gypsum powder ball mill can only use a steel ball fixed ratio to produce a single product.

Drying capacity: When the ball mill grinds wet raw materials, because of the limited gas flow through the ball mill, it is usually necessary to install additional drying equipment in front of the ball mill.

Device configuration space: The gypsum powder ball mill occupies a large space.

Feed particle size: Gypsum powder ball mill is limited by the maximum steel ball diameter, can only feed small raw materials.

Fineness of product: The particle size distribution ratio of the finished ultrafine powder ground by ball mill is relatively low.

Grinding product replacement time: Gypsum powder ball mill needs a long time to clean up the material of the last grinding when it is converted to grinding other materials, and only after cleaning up can the new material be grinding.

Contamination of abrasive materials: Because the ball mill needs to grind the material through the medium, there will be a certain degree of pollution, and the whiteness of the final product is low.

Grinding efficiency: Gypsum powder ball mill is the use of collision friction grinding materials, so the grinding efficiency is low.

Initial investment cost: The initial investment cost of a gypsum powder ball mill is lower than that of an ultra-fine vertical mill.

Operating cost: Gypsum powder ball mill because of grinding medium consumption and power consumption is high, so the operation cost is relatively high.

Noise: Gypsum powder ball mills are noisier.

Product particle shape: The sphericity of finished particle size after grinding by gypsum powder ball mill is better.

Sensitivity to external conditions: Ball mill has low sensitivity to external conditions and is not easily affected.

If you want to know more about it, click here. We’ll get in touch with you as soon as possible.