FW series gypsum powder multi-head classifier

Table of Contents

- 1 Product overview of FW series gypsum powder multi-head classifier

- 2 Product advantage of FW series gypsum powder multi-head classifier

- 3 Product parameter of FW series gypsum powder multi-head classifier

- 4 Product maintenance of FW series gypsum powder multi-head classifier

- 5 Manufacturer Introduction of FW series gypsum powder multi-head classifier

- 6 FAQ

Product overview of FW series gypsum powder multi-head classifier

FW series gypsum powder multi-head classifier is mainly applied to classify 3-45 microns ultra-fine powders. It is not only classy scalable spherical, flake, needle-like particles, but also for the particles with different densities.

The whole classifying system consists of a classifier and cyclone separator, dust cleaner and blower. The materials are sent to the separating field by inhaling air blower from the bottom feeding inlet. Coarse and fine materials are separated by powerful centrifugal force generated by high speed rotating classifying turbine. The qualified fine powder is sent to cyclone separator or dust cleaner to be collected by close blade; the unqualified coarse powder with little fine powder hit the classifier surface and fell down to the second air inlet along the cylinder wall. The coarse and fine powders are separated by the strong screening effect of secondary air. The fine powders are brought to separating field for secondary classification, the coarse powders fall down and are discharged.

Product advantage of FW series gypsum powder multi-head classifier

1. The fineness can reach D97 (2-45micron) and be adjusted, which is convenient to change different fineness products.

2. FW series gypsum powder multi-head classifier classification efficiency can reach 60%-80%.

3. FW series multi-head classifier horizontal classifying turbine unit with high speed and accurate vertex cutting.

4. FW series gypsum powder multi-head classifier can be used with vibration mill, Raymond mill and other grinding equipment to form a closed loop.

5. PLC automatic control system, running real-time display, easy to operate. 6. Negative pressure operation, dust emission do not exceed 40mg/m³. Noise is lower than 75dB (A) through soundproof measures.

Product parameter of FW series gypsum powder multi-head classifier

Model |

FW630/3 | FW630/4 | FW630/6 | FW800/3 | FW800/4 | FW800/6 |

| Capacity (t/h) |

1-5 | 2-8 | 3-10 | 2-8 | 3-10 | 5-15 |

| Partical size (mm) |

3-45 | 3-45 | 3-45 | 4-45 | 4-45 | 4-45 |

| Efficiency (%) |

60-80 | 60-80 | 60-80 | 60-80 | 60-80 | 60-80 |

| Power (kw) |

135-155 | 170-190 | 250-290 | 180-200 | 220-290 | 290-390 |

Product maintenance of FW series gypsum powder multi-head classifier

(1) Perform small maintenance on FW series gypsum powder multi-head classifier after 1-3 months of use.

1. Check the wear of small blades and large blades, replace small blades, and correct the bending degree of large blades.

2. Check the FW series gypsum powder multi-head classifier wear of the lower support and replace the lower support.

3. Check the lubrication of the reducer, replace or add lubricating oil.

4. Check whether the multi-head classifier electrical equipment is in good condition and the motor temperature shall not exceed 60 degrees.

(2) Perform moderate maintenance on FW series gypsum powder multi-head classifier after 12 months of use.

1. Check the wear condition of the reducer gear of the multi-head classifier.

2. Check the wear of the upper support bushing.

3. Replace the locking plate of the upper support part.

4. Replace FW series gypsum powder multi-head classifier some bearings.

(3) Perform big maintenance on FW series gypsum powder multi-head classifier after 12 months of use.

1. Replace the main shaft of the FW series gypsum powder multi-head classifier.

2. Repair the tank of the classifier by welding.

3. Tighten or replace the classifier blade support.

4. Repair or replace the FW series gypsum powder multi-head classifier motor.

Manufacturer Introduction of FW series gypsum powder multi-head classifier

Company profile

Shanghai Clirik Machine Co., Ltd. has a professional technical force and perfect production capacity. The company’s products are widely used in mining, road construction, bridge construction, housing construction and other industries, crusher, ultra-fine grinding mill, feeder, vibrating screen, sand washing machine, conveyor and other equipment and series of products, all passed the ISO9001:2000 standard quality certification.

Our Technology

Clirik has more than 12,000 square meters of standardized production plant, including a processing workshop, assembly workshop, painting and sandblasting workshop, trial machine debugging workshop, finished product placement workshop, etc. The workshop is equipped with more than 100 high-end CNC machine tools of well-known foreign brands.

From drawing, assembly to debugging, the equipment manufacturing has gone through thousands of processes, including resizing, cutting, grinding, trimming, heating, forging, turning, milling, grinding and drilling, inspection, painting, assembly and test machine. Each manufacturing process is repeatedly verified by our engineers to ensure the reliability and integrity of each device. Raw materials are related to the quality of products. Our engineers have strict requirements on the selection of raw materials. National standard steel is used.

Our Transportation

We can not only provide you with express delivery, sea transportation, land transportation, air transportation, self-transport and other ways to deliver goods according to your needs, but also package the main machine and parts of the grinding equipment you buy to avoid damage in the process of transportation, to ensure that you can assemble and produce the equipment after receiving it.

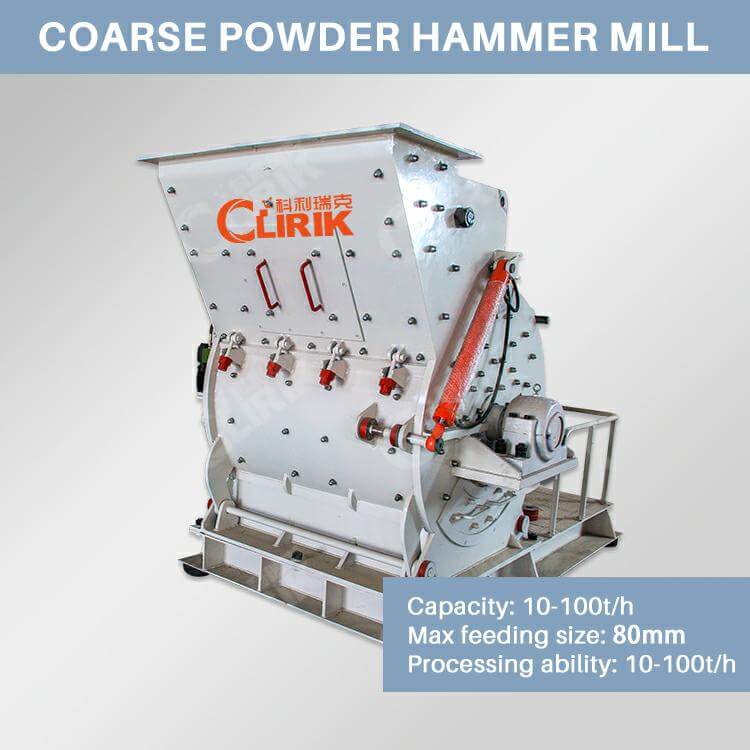

Hot Product

In addition to FW series gypsum powder multi-head classifier, the company also has other related gypsum powder production line equipment.

Customer Case

Video of the customer cases of FW series gypsum powder multi-head classifier applied to the gypsum powder production line.

For more information, please click here to consult us.

FAQ

1. Do you have an after-sales service?

All of our products have after-sales quality assurance services.

2. How long is your delivery time?

Generally, it is 10-15 days if the goods are in stock.

or it is 15-20 days if the goods are not in stock, it is according to quantity.

3. How to carry out transportation?

Express, sea transport, land transport, air transport, self – lift can be based on your needs.

4. What are the terms of payment?

L/C, Western Union, D/P, D/A, T/T, MoneyGram, Alibaba.com Pay, cash.

5. Are you a middle man or a manufacturer?

Our Shanghai Clirik Machinery is a professional mining equipment manufacturer.

We are in PuDong new area, HeQing town, FuQing road, No. 19, Shanghai, China.