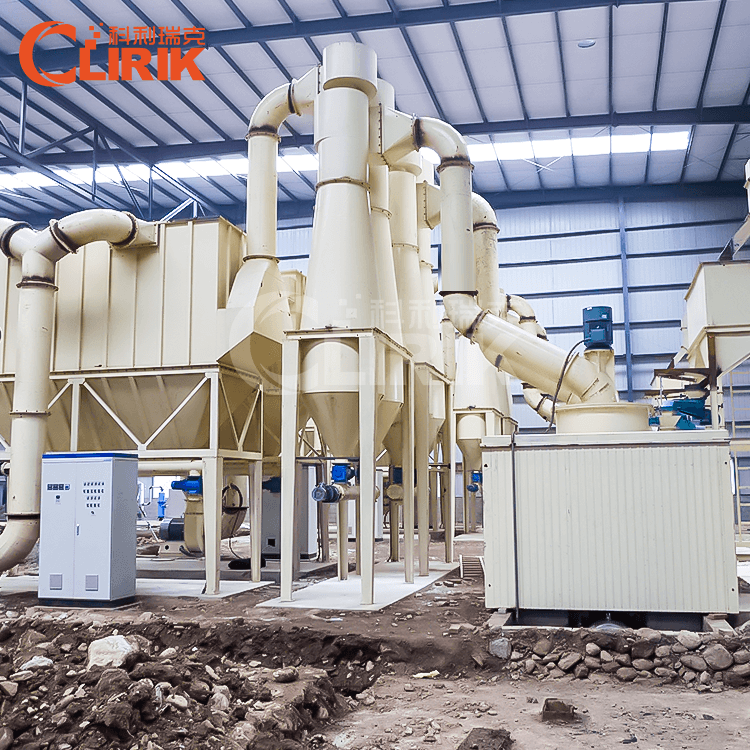

Gypsum ultrafine powder grinding mill -case in Vietnam

Release Time:2022-07-22

Table of Contents

Gypsum ultrafine powder grinding mill -case in Vietnam

Processed Material: Gypsum

Using Machine : HGM series Gypsum ultrafine powder grinding mill

Finished Fineness: 600mesh

Production Output: 20ton per hour

Application Field: Gypsum powder is widely used in construction, food, medicine, paint fillers and other industries.

ABOUT THIS CASE

This customer in Vietnam is processing gypsum, and he needs to produce 600 mesh gypsum, with an hourly output of more than 20 tons.

According to customer needs, we recommend the ideal equipment Gypsum ultrafine powder grinding mill developed and produced by Clirik.

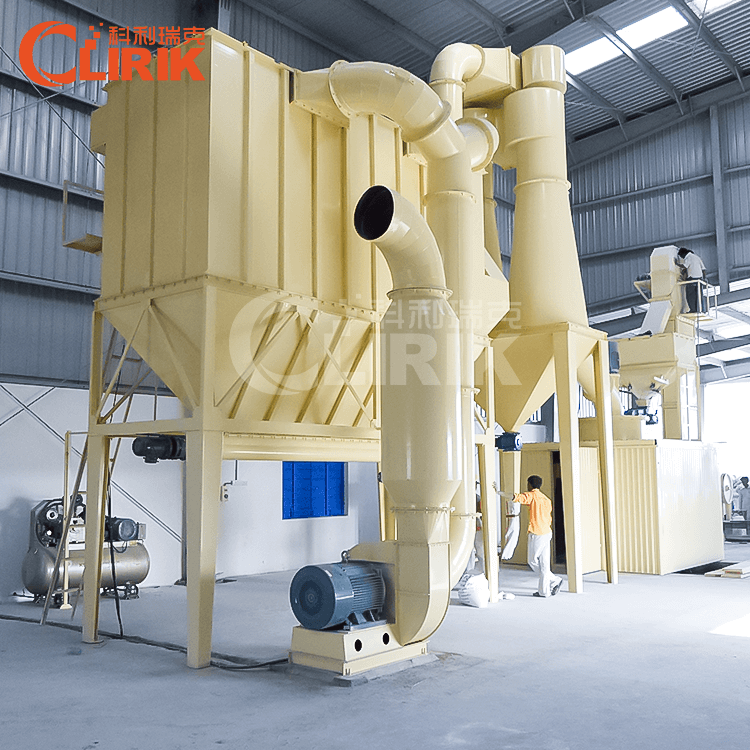

This Gypsum ultrafine powder grinding mill not only environmental protection and energy saving, high powder yield, large output, long service life of equipment and a high degree of automation but also can produce 325-2500 mesh gypsum powder, and the fineness can be adjusted freely.

In addition, the gypsum powder ultrafine grinding mill can also grind 100+ kinds of non-metallic ores, such as calcium carbonate, carbon black, calcite, mica, and so on.

WHY CHOOSE GYPSUM POWDER ULTRAFINE GRINDING MILL?

CLIRIK recommends customers to use Gypsum ultrafine powder grinding mill to grind in the production and processing of fine powder. The gypsum powder mill has comprehensive mechanical crushing properties such as rolling, grinding and impact.

The grindable powder can be adjusted between 325-2500 mesh and application widely. If the customer needs to widen the downstream ore powder application market, theGrinding can be carried out without additional grinding equipment, increasing revenue.

The gypsum powder pulverized mill has a large crushing ratio, high energy utilization rate, high degree of automation and long service life. It is a mineral powder processing mill equipment to enhance output and decrease consumption.

The following is a detailed description of the advantages of the Gypsum ultrafine powder grinding mill :

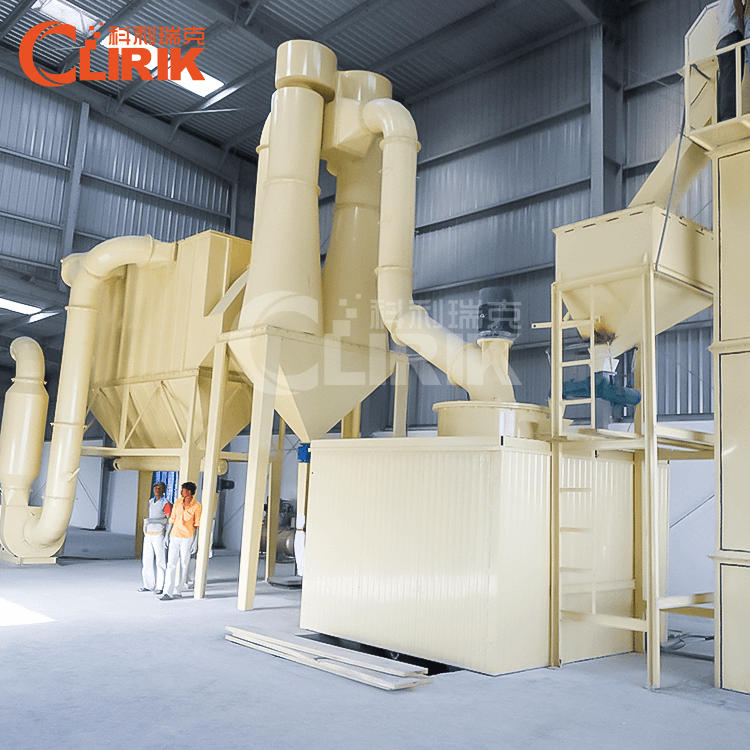

1.Large crushing ratio and high energy utilization

Compared with jet mill, mixing grinder and ball mill of same finished product size and motor power, HGM Micro-Powder Mill has double capacity and saves 30% energy.

2.High classification efficiency

The forced turbine classification system is adopted, with more uniform and fine particle size. The production of finished products with different fineness can meet the market demand and improve the market competitiveness.

3.High efficiency dust collection

Using a full pulse dust collection system, the efficiency is up to 99%, green and more environmentally friendly.

4.Long Life of Spare Parts

The grinding wheel and ring of the equipment are made of special wear-resistant steel. The equipment has a longer service life, less wear, compact structure and good shock absorption performance.

ABOUT RAW MATERIAL GYPSUM

Gypsum also known as plaster stone, gypsum is mainly composed of calcium sulfate, widely used in construction, chemistry, agriculture and other industries.

The following is a detailed description of the application of the gypsum powder :

Construction

A: Anhydrite cement and cementitious material: adding proper amount of real activator can produce a cement or cementitious material, suitable for the reinforcement of soft soil foundation, wall painting, mechanical model, tunnel support and production of fiber pressure plate, etc.

B: Used as co-solvent and purifier in glass production process.

C: Used as filler in plastic, rubber, paint, asphalt, linoleum and other industrial production.

D: Main raw materials of concrete expansion agent, anti-crack agent and self-leveling mortar.

E: Cast-in-place pile and deep mixing pile are used as large expansion materials to increase friction resistance.

F: Used as compound mineralizer in the production of special cement.

Agriculture

A: Improve soil, adjust ph, suitable for saline-alkali land, red soil and other soil improvements.

B: Edible fungus is used as calcium and sulfur compound mineral fertilizer to adjust the ph of culture medium.

C: used as compound mineral feed additive in poultry and livestock feed.

Chemical

A: Sulfuric acid production, with light cement production.

B: Produce ammonium sulfate, and produce light calcium carbonate.

WHY CHOOSE CLIRIK?

Clirik Ultrafine powder technology is a trusted partner. We have been focusing on the research and development and production of ultrafine mills. Continuous improvement and excellence to create valuable grinding equipment for customers.

Full service:

Raw material testing-program design-equipment manufacturing-installation-commissioning-technical training-up to standard and production-after-sales service.

Factory direct supply:

More than 30 years of experience in R&D and manufacturing, and 120+ countries and regions coverage. The source manufacturer has no middleman, higher cost performance, and excellent quality, ingenuity.

Ingenuity:

Clirik provides solutions for calcite grinding/crushing and screening, tailor-made solutions for you.

Automatic equipment production, the pipe wall is thicker and resistant to compression and deformation, environmentally friendly materials are harmless, and support customization.